When costs rise, and performance varies, you deserve clarity you can trust. Enveyo’s Shipping Simulation & Modeling shows you exactly how every carrier, every rate, and every network decision will impact your bottom line before you make a move.

DHL AVG Shipment Charge

FEDEX AVG discount

Load historical shipping data

Simulate multiple scenarios

Make changes confidently

When you can’t see the impact of your shipping decisions, you’re not just guessing, you’re gambling. In a world where one wrong variable can change everything, failing to model your shipping decisions is the most expensive decision you can make.

Without clear shipping simulation and modeling:

Changes fail & costs rise when the impact isn’t visible.

New network decisions introduce delays.

Accessorial errors quietly cost millions in budget.

Your team stays constantly reactive and stressed.

Logistics moves fast. Spreadsheets can’t keep up. Changing one variable—your volume, a carrier contract, a new location—can shift costs and performance instantly.

Enveyo helps you take control with practical, real‑world modeling.

Run powerful analyses without technical lift. Upload, simulate, adjust, and compare—your data does the heavy lifting.

Find out where you’re overspending, optimal carrier combinations, and how to improve today’s operations with minimal disruption.

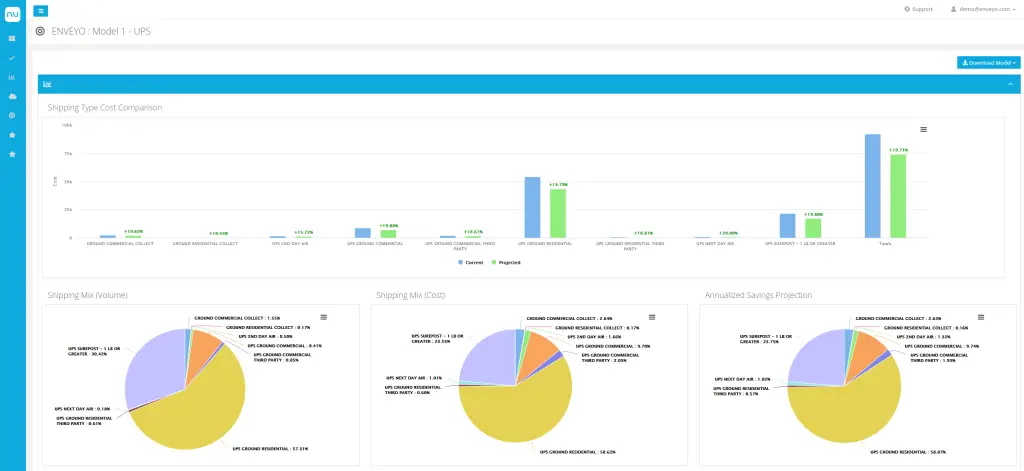

Model future carrier agreements, new fulfillment nodes, service changes, and packaging adjustments before you invest.

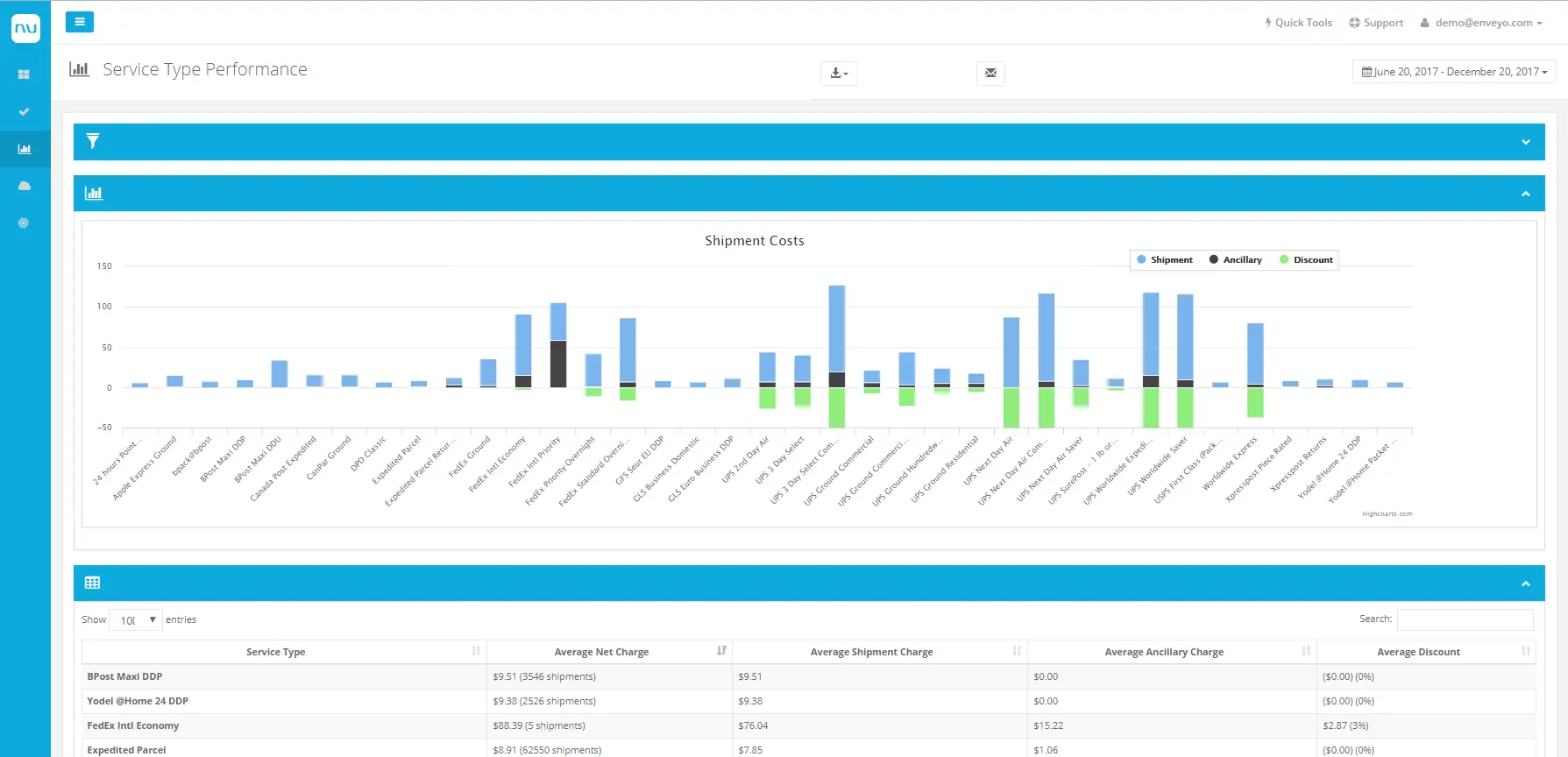

Gain a full picture of your spend, carrier mix, service selection, accessorial exposure, and performance gaps.

Replace reactive choices with data‑backed clarity. Every scenario. Every outcome. Clear and side‑by‑side.

Logistics is full of moving parts. Simulation ties it all together.

Shipping decisions are complex and risky. Simulation shows how changes will play out before you make them—so you reduce surprises, control costs, and move forward with confidence.

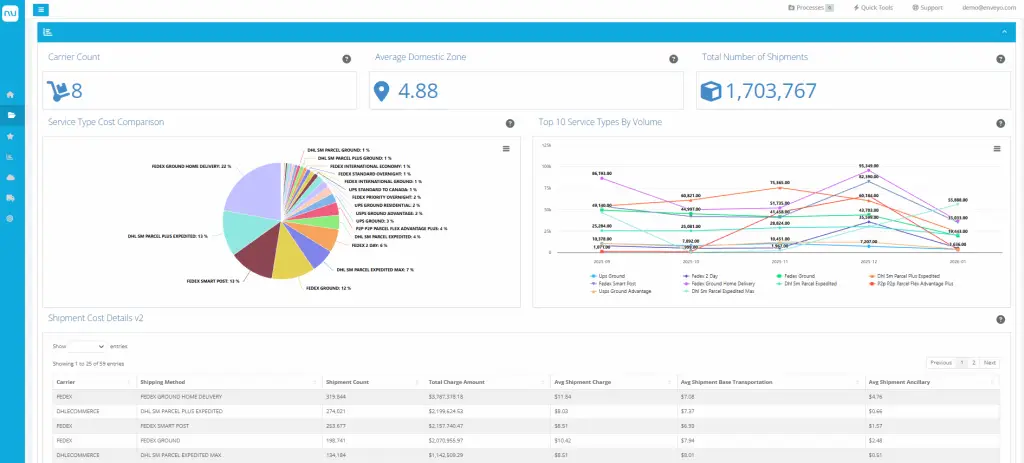

See which regional, national, or hybrid combination delivers the best cost-to-service ratio.

Model impacts across stores, DCs, 3PLs, marketplaces, and more.

Test new locations, N+1 strategies, and distribution footprints.

Compare incentives, discounts, minimums, and service-level trade-offs using your real shipping patterns.

Total Number of Shipments

Surface fee exposure and model rule changes before carriers implement them.

Predict cost and service outcomes as volume, weight breaks, or SKU mix shift.

Win more deals by modeling client data and presenting insights—in minutes, not days.

Test routing logic changes, business rules, carrier compliance thresholds, and more.

Predictive modeling shouldn’t feel intimidating. With Enveyo, it’s practical, approachable, and built for the real world you operate in every day. No jargon. No heavy lift. Just a clear, step‑by‑step way to test decisions before they cost you.

Upload your shipment data, invoices, or forecasts—Enveyo turns it into clear, usable insight so every “what if?” becomes simple, visible, and decision‑ready.

UniUni Total Shipments

Ups 3 day Select

UPS Next Day Air

Now you explore. Try new carriers, tweak packaging, adjust rules, or test locations—quick, simple, and grounded in how your operation really works.

See what’s working fast, spot issues early, and make the right call with confidence. As things change, your models update too—keeping improvements simple.

“We can model out a full year’s worth of 10 million packages and see how that’s actually going to result in a change that we make in the carrier.”

Operations Supervisor at GEODIS

We know what it’s like to overpay for your logistics software that underperforms and is loaded with limitations. With Enveyo, you get unlimited logistics capability without the inflated price tag.

Onboard any carrier in any region.

Unify every shipment, order, and event.

Your growth should fuel savings, not penalties.

Give visibility to everyone who needs it.

One platform for analysis → modeling → execution → tracking → audit.

Enveyo’s platform goes beyond simulation and gives you everything you need to model, predict, and take control:

Clear, trusted reporting teams and customers can rely on.

Smarter pricing and scenario decisions.

Automated parcel management that saves costs.

Real‑time updates your clients can trust.

Automatic recovery that protects margins.

We take a quick look at your biggest challenges and show you how your shipping operations can improve—where costs slip, where delays show up, and how clearer data puts you back in control.

Once you’re ready, we make the switch easy—bringing your data, carriers, and workflows into one platform without disrupting operations, so you get clear visibility from day one.

With unlimited visibility, automation, and insight in one place, you finally get control. Your team makes faster decisions, avoids costly mistakes, and runs logistics that feel clear, predictable, and scalable.

Your guide to stop overspending and start winning.

Get ahead with the guide that shows you how to replace guesswork with clarity, uncover hidden savings, stress‑test strategies, and build a smarter, more resilient logistics network.

Explore how leading logistics teams use advanced modeling to predict outcomes, prevent costly mistakes, and make smarter, data‑driven decisions.

Shipping simulation is the process of modeling real shipping data to see how changes—like carrier swaps, rate increases, or network changes—will impact cost, service, and performance before they happen. It helps logistics teams make decisions with confidence instead of guessing.

Logistics modeling reveals where costs are really coming from, including accessorial fees, zone creep, GRIs, and service mismatches. By simulating different scenarios, teams can identify lower-cost options without sacrificing delivery performance.

Most shipping simulations use historical shipment data, carrier invoices, rate cards, and basic forecasts. Even partial data can deliver meaningful insights, and models become more accurate as more data is added over time.

Yes. Shipping simulation allows you to model proposed carrier rates, discounts, minimums, and incentives using your real shipping patterns. This shows the true financial impact of a contract before you sign—and helps you negotiate from a position of strength.

Analytics and reports show what has already happened. Shipping simulation shows what will happen if you make a change. It’s the difference between looking in the rearview mirror and seeing the road ahead.

Absolutely. Simulation can model new DC locations, facility expansions, and network changes to show how they affect transit times, costs, and service levels—before you invest time or capital.

Yes. 3PLs use simulation to model client data during the sales process, demonstrate value quickly, and design optimized carrier strategies. It helps shorten sales cycles and build trust with data-backed insights.

Accuracy depends on data quality, but modern simulation platforms use historical performance, carrier behavior, and real-world constraints to produce highly reliable forecasts. Most teams use simulation to narrow risk—not chase perfection.

Many teams uncover actionable insights within days of uploading data. Simulation delivers fast wins by highlighting obvious inefficiencies, then continues to add value as strategies evolve.

Shipping simulation is ideal for shippers and 3PLs managing high parcel volumes, complex carrier mixes, or rising costs—especially teams responsible for cost control, service performance, and long-term logistics strategy.

We'll set up a time to meet.

Together, we'll walk through your goals and challenges.

If it’s a fit, we map out a clear path forward.